Contact Us for a Consultation

Please inquire using the Contact Us page. We will confirm the details and contact you.

Confirmation of the Data

Please provide us with the design files using any of the formats listed below.

Proposal and Cost Estimate

Once we confirm the design specifications, we will submit a proposal along with the cost estimate. We will begin the prototyping process once the customer approves the proposal.

Microfluidic Chip Delivery

We can prepare the technology drawings for you. Please contact us to discuss this further.

Separate fees may apply for this service.

|

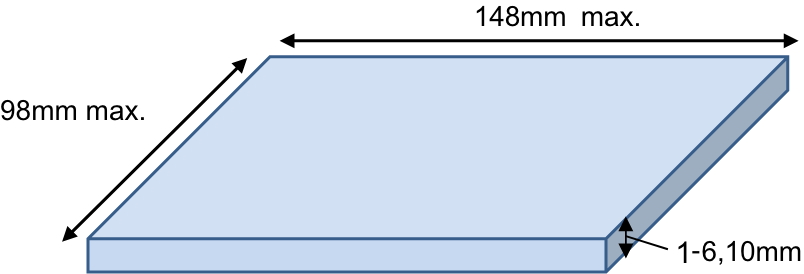

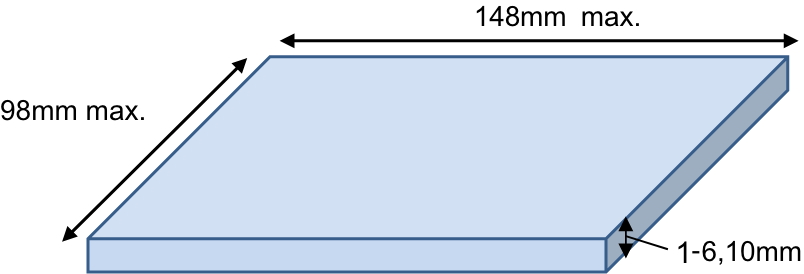

Maximum size | 148mm×98mm |

|---|---|---|

| Thickness | 1,2,3,4,5,6,10mm |

|

|

| Maximum size | 148mm×98mm |

|---|---|

| Thickness | 1,2,3,4,5,6,10mm |

|

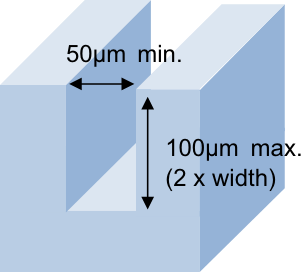

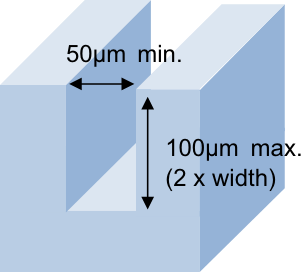

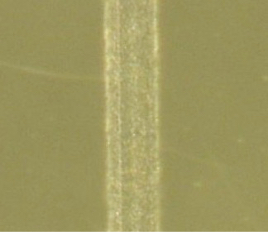

Minimum channel width | 50μm±15μm |

|---|---|---|

| Maximum channel depth | (2 x width) |

|

|

| Minimum channel width | 50μm±15μm |

|---|---|

| Maximum channel depth | (2 x width) |

|

End Mill | Diamond |

|---|---|---|

| Ra | 0.017μm | |

| Width | 200μm | |

| Depth | 100μm |

|

|

| End Mill | Diamond |

|---|---|

| Ra | 0.017μm |

| Width | 200μm |

| Depth | 100μm |

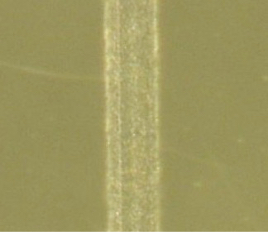

Diamond end mill can achieve lower surface roughness, however carbide end mill is required to achieve minimum channel width of 50μm

|

End Mill | Cemented Carbide |

|---|---|---|

| Ra | 0.048μm | |

| Width | 50μm | |

| Depth | 50μm |

|

|

| End Mill | Cemented Carbide |

|---|---|

| Ra | 0.048μm |

| Width | 50μm |

| Depth | 50μm |

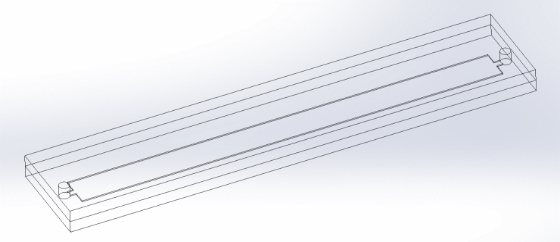

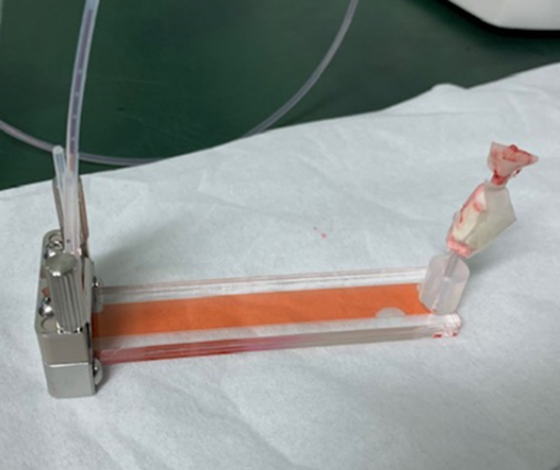

Zeon’s bonding withstand the pump pressure of 500kPa under the following conditions

| Chip Size | 70mm×15mm | |

|---|---|---|

| Channel Profile | Width | 5mm |

| Depth | 0.2mm | |

| Length | 60mm | |

| Plate Thickness | Upper plate | 2mm |

| Lower plate | 2mm | |

| Test Liquid | Distilled water (food coloring agent) | |

| Pump | P-Pump (Dolomite) | |

| Chip Size | ||

|---|---|---|

| 70mm×15mm | ||

| Channel Profile | ||

| Width | 5mm | |

| Depth | 0.2mm | |

| Length | 60mm | |

| Plate Thickness | ||

| Upper plate | 2mm | |

| Lower plate | 2mm | |

| Test Liquid | ||

| Distilled water (food coloring agent) | ||

| Pump | ||

| P-Pump (Dolomite) | ||

Learn more about COP